A revolutionary 3D printing technique has emerged from researchers at EPFL, promising metals up to 20 times stronger than before. This breakthrough uses hydrogels to print ultra-strong metals and ceramics, opening doors for advanced manufacturing and engineering. The technique could reshape industries from aerospace to automotive by producing components that are both lighter and more durable.

How the New 3D Printing Method Works

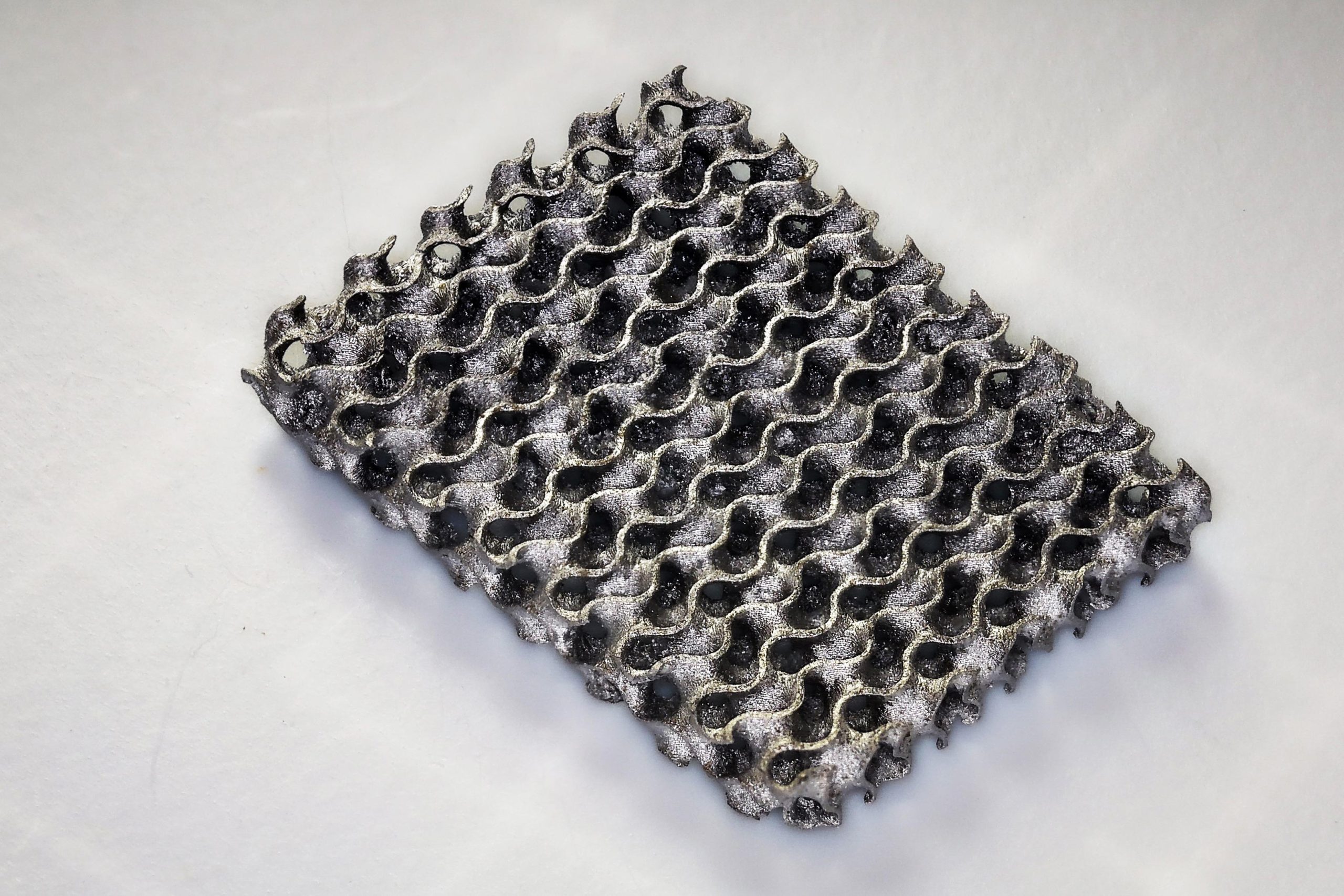

The innovative process relies on hydrogels as a medium, which allows for precise control over the material’s microstructure during printing. By fine-tuning these structures, scientists can dramatically boost the strength and resilience of printed metals and ceramics. Unlike traditional manufacturing, this method offers greater flexibility in design and material properties, making it ideal for customized, high-performance parts.

Implications for Industry and Technology

This advancement in 3D printing could transform the way we produce everything from airplane parts to medical devices. The ability to create stronger, lighter, and more complex shapes with less waste sets a new standard for sustainable manufacturing. As industries adopt this technology, we can expect faster development cycles, improved product performance, and significant cost savings.

Sources:

Source